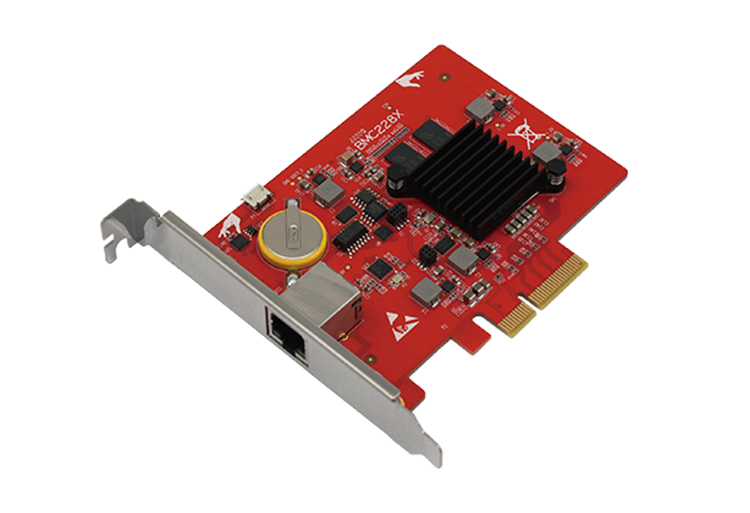

FSCUT2000C, FSCUT2000E, FSCUT4000E

Low / Medium Power Control System

The FSCUT2000C is a medium-power laser cutting system designed as a comprehensive open-loop control solution for the sheet metal fabrication industry. It is easy to install and adjust, offers excellent performance, and provides fully integrated solutions.

The FSCUT2000E, with power ranges from 1,000W to 4,000W, is a cost-effective CNC system for laser cutting, based on EtherCAT bus technology. It supports motion control, laser control, and cutting gas control, making it suitable for a wide range of industries.

The FSCUT4000E is a versatile, cost-effective laser control system designed for cutting power ranges from 1.5kW to 8kW. It integrates motion control, laser control, and cutting gas control, and is commonly used in industries such as sheet metal fabrication, kitchenware, and lighting fixtures.

Product Features

Low / Medium Power 2D FSCUT Selection Guide

Basic

- 1-4kW

- Non-bus System

- Safe Operation Monitor (x)

- High-Speed Find Edge (x)

- One-Path FlyCut (x)

- Circle Center (x)

- Nest (CypCut)

- Inkjet Print (x)

- Limitless Coil (x)

- QR Code Import (x)

- Multi-Station Machining (x)

- Visual Remnant (x)

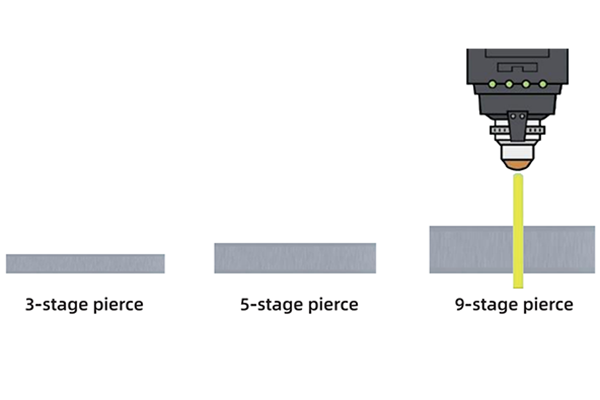

- Pierce Stage (3-Stage)

- Fast Cutting (x)

- Slag-Free Cutting (x)

- Smooth MicroJoint (x)

- Auto Recut (x)

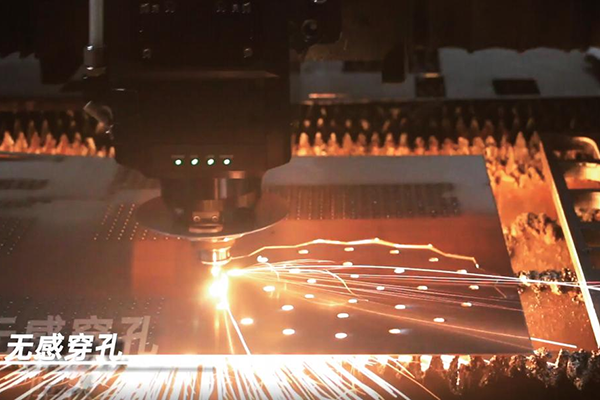

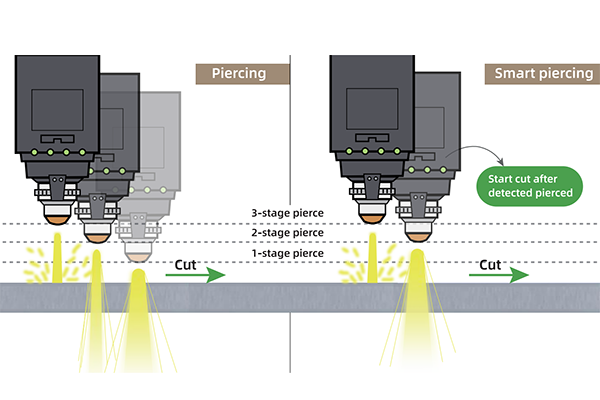

- Smart Piercing (x)

- Co-edged Piercing Monitoring (x)

Standard

- 1-4kW

- Bus System

- Safe Operation Monitor (x)

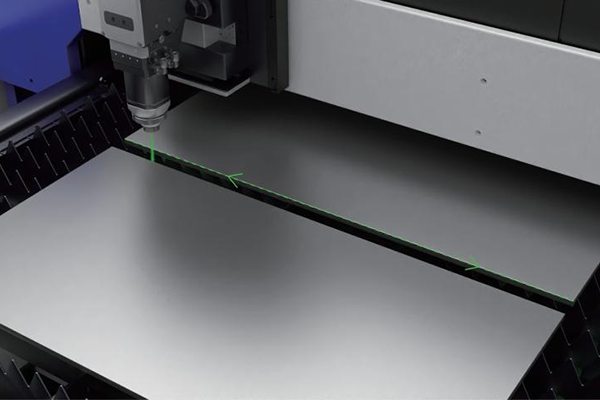

- High-Speed Find Edge (✓)

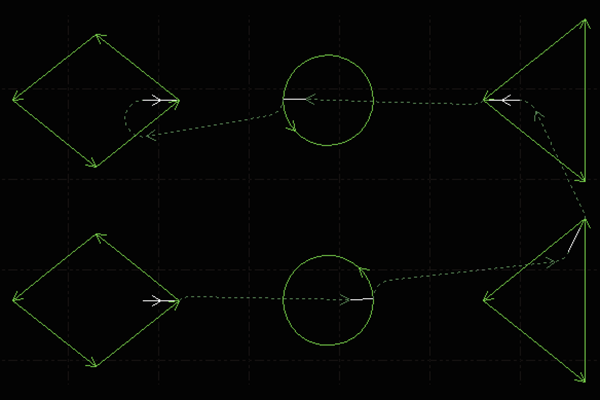

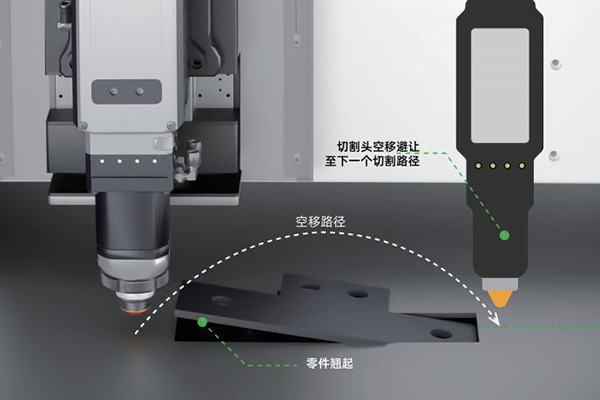

- One-Path FlyCut (✓)

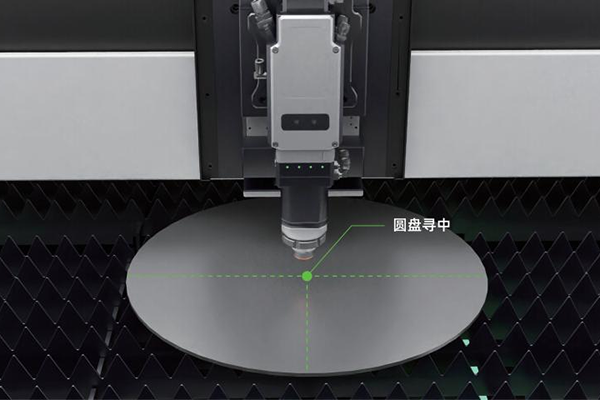

- Circle Center (✓)

- Nest (CypNestSE)

- Inkjet Print (✓)

- Limitless Coil (✓)

- QR Code Import (✓)

- Multi-Station Machining (✓)

- Visual Remnant (x)

- Pierce Stage (3-Stage)

- Fast Cutting (✓)

- Slag-Free Cutting (x)

- Smooth MicroJoint (x)

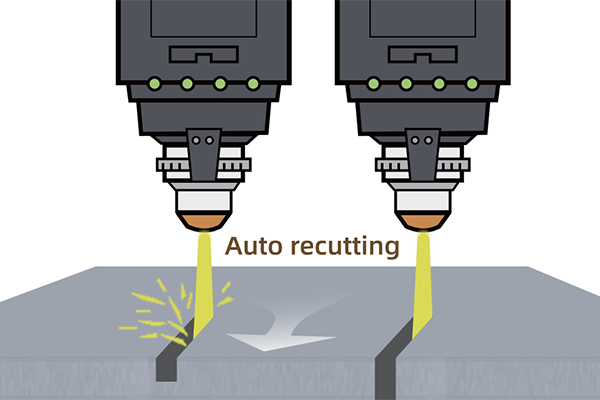

- Auto Recut (x)

- Smart Piercing (x)

- Co-edged Piercing Monitoring (x)

Premium

- 1.5-8kW

- Bus System

- Safe Operation Monitor (x)

- High-Speed Find Edge (✓)

- One-Path FlyCut (✓)

- Circle Center (✓)

- Nest (CypNestSE)

- Inkjet Print (✓)

- Limitless Coil (✓)

- QR Code Import (✓)

- Multi-Station Machining (✓)

- Visual Remnant (x)

- Pierce Stage (3-Stage)

- Fast Cutting (✓)

- Slag-Free Cutting (x)

- Smooth MicroJoint (✓)

- Auto Recut (x)

- Smart Piercing (x)

- Co-edged Piercing Monitoring (x)

FSCUT6000, FSCUT8000C, FSCUT8000A PLUS+

High Power Control System

The FSCUT6000, with power ranges from 6,000W to 15,000W, is based on EtherCAT bus technology and supports motion control, laser control, and cutting gas control. It is commonly used in industries such as sheet metal fabrication, kitchenware, lighting, and other related sectors.

The FSCUT8000C is a high-end intelligent EtherCAT bus controller designed for high-power fiber lasers above 8kW. It features out-of-the-box service, easy installation and adjustment, and full solution capabilities. It supports customized, automated, and digital solutions.

The FSCUT8000A PLUS+ is a specialized bus system for high-power applications. It supports customization, automation, and informatization solutions, making it the leading-edge EtherCAT laser cutting control system on the market. It is the perfect solution for high-end laser cutting CNC machine tools.

Product Features

High Power 2D FSCUT Selection Guide

Economic

- 6-15kW

- Bus System

- Safe Operation Monitor (x)

- High-Speed Find Edge (✓)

- One-Path FlyCut (✓)

- Circle Center (✓)

- Nest (CypNestSE)

- Inkjet Print (✓)

- Limitless Coil (✓)

- QR Code Import (✓)

- Multi-Station Machining (✓)

- Visual Remnant (x)

- Pierce Stage (5-Stage)

- Fast Cutting (✓)

- Slag-Free Cutting (✓)

- Smooth MicroJoint (✓)

- Auto Recut (x)

- Smart Piercing (x)

- Co-edged Piercing Monitoring (x)

Premium

- 8-100kW

- Bus System

- Safe Operation Monitor (✓)

- High-Speed Find Edge (✓)

- One-Path FlyCut (✓)

- Circle Center (✓)

- Nest (CypNest)

- Inkjet Print (x)

- Limitless Coil (x)

- QR Code Import (✓)

- Multi-Station Machining (✓)

- Visual Remnant (✓)

- Pierce Stage (9-Stage)

- Fast Cutting (✓)

- Slag-Free Cutting (✓)

- Smooth MicroJoint (✓)

- Auto Recut (✓)

- Smart Piercing (✓)

- Co-edged Piercing Monitoring (✓)

Flagship

- 8-100kW

- Bus System

- Safe Operation Monitor (✓)

- High-Speed Find Edge (✓)

- One-Path FlyCut (✓)

- Circle Center (✓)

- Nest (CypNest)

- Inkjet Print (x)

- Limitless Coil (x)

- QR Code Import (✓)

- Multi-Station Machining (✓)

- Visual Remnant (✓)

- Pierce Stage (9-Stage)

- Fast Cutting (✓)

- Slag-Free Cutting (✓)

- Smooth MicroJoint (✓)

- Auto Recut (✓)

- Smart Piercing (✓)

- Co-edged Piercing Monitoring (✓)

Yupec Laser is a leading provider of advanced fiber laser solutions in Europe, specializing in the sales, technical support, and service of Raycus fiber lasers.

With years of experience and a team of industry experts, we will be happy to help you with all your laser and laser application needs.

For more information about our products and services, please feel free to get in touch with us. We look forward to collaborating with you and driving innovation together.