When the fiber laser output head and laser cutting head become contaminated, the pollutants will absorb laser energy, causing localized temperature rise and triggering the thermal lens effect. This phenomenon significantly reduces laser focusing performance and directly affects processing accuracy. In severe cases, it may even cause ablation damage to the mirror coating, necessitating the replacement of optical components.

However, in practice, the installation and cleaning of the fiber laser output head are not as complicated as you might think. Below are detailed steps and precautions for installation and cleaning.

Preparation and Conditions Before Installation

Environmental Requirements

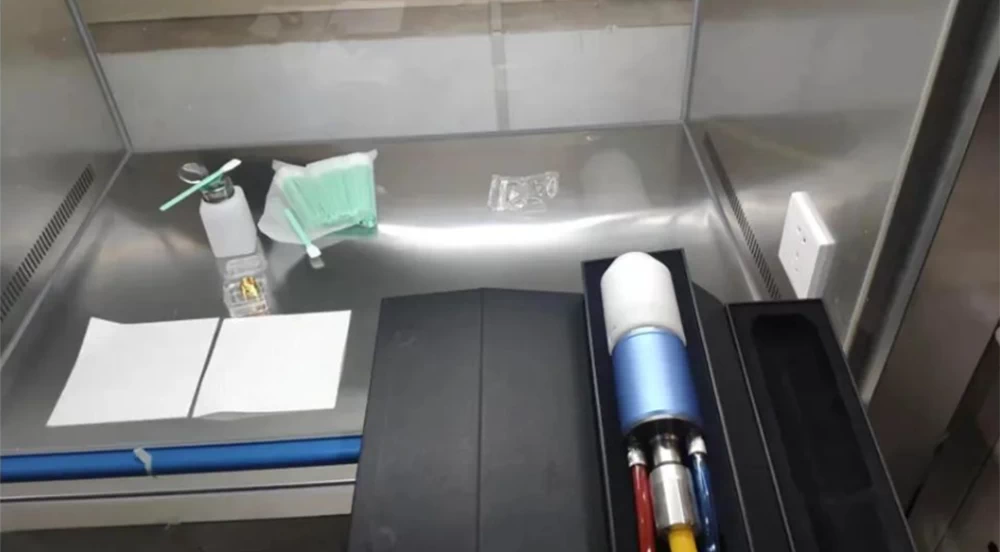

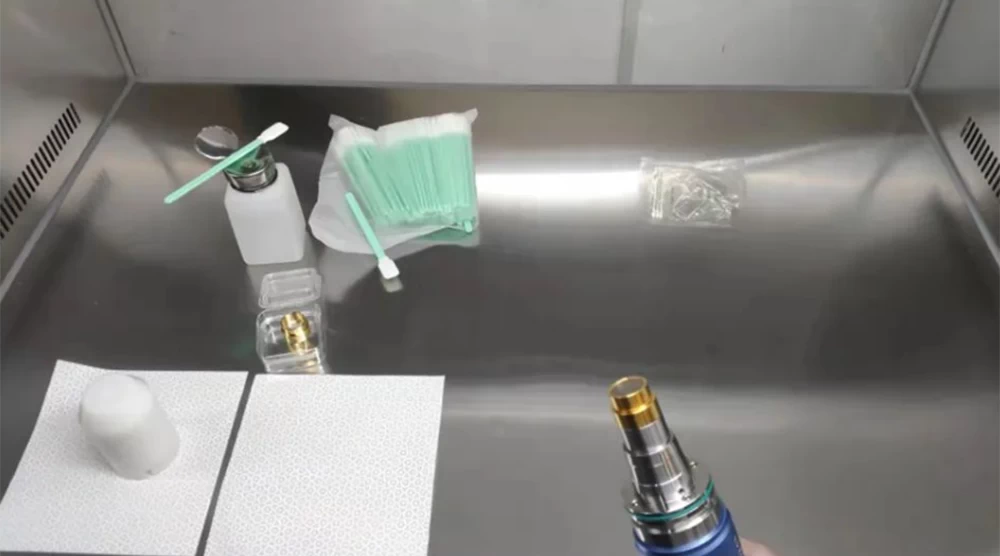

Auxiliary Tools

Installation & Cleaning Steps

Installation Precautions

Share The Post Now:

You Might Also Like

Yupec Laser is a leading provider of advanced fiber laser solutions in Europe, specializing in the sales, technical support, and service of Raycus fiber lasers.

With years of experience and a team of industry experts, we will be happy to help you with all your laser and laser application needs.

For more information about our products and services, please feel free to get in touch with us. We look forward to collaborating with you and driving innovation together.