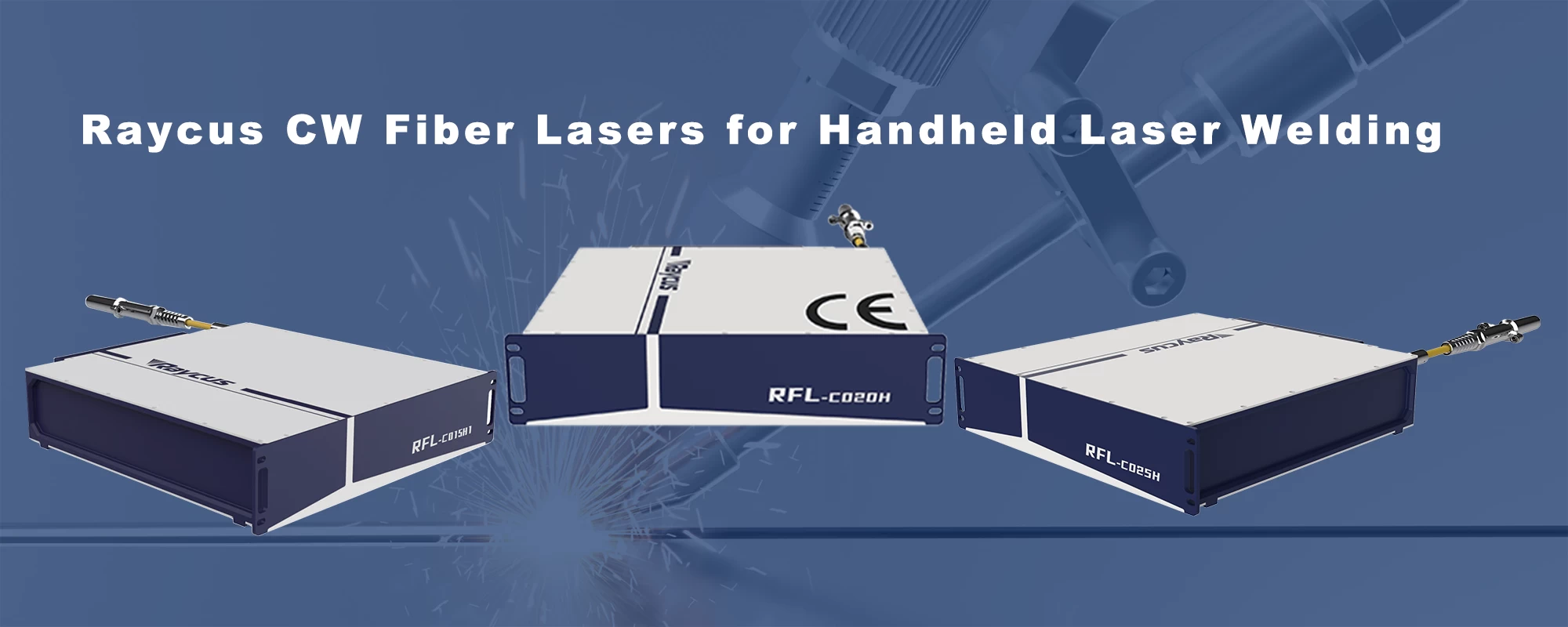

In the fiber laser market, working power is often regarded as the sole standard for measuring the performance of equipment. However, in practical applications, the power level does not necessarily correlate directly with the quality of the processing. Customers are more concerned with how to achieve better processing efficiency and results in less time, so they can quickly recover their equipment costs and achieve profitability. To meet this demand, Raycus has introduced the high-performance series cw fiber lasers, designed to provide efficient and high-quality processing.

Raycus High-Performance CW Fiber Laser Source

Raycus HP-Series Fiber Lasers – 6 Key Performance Improvements

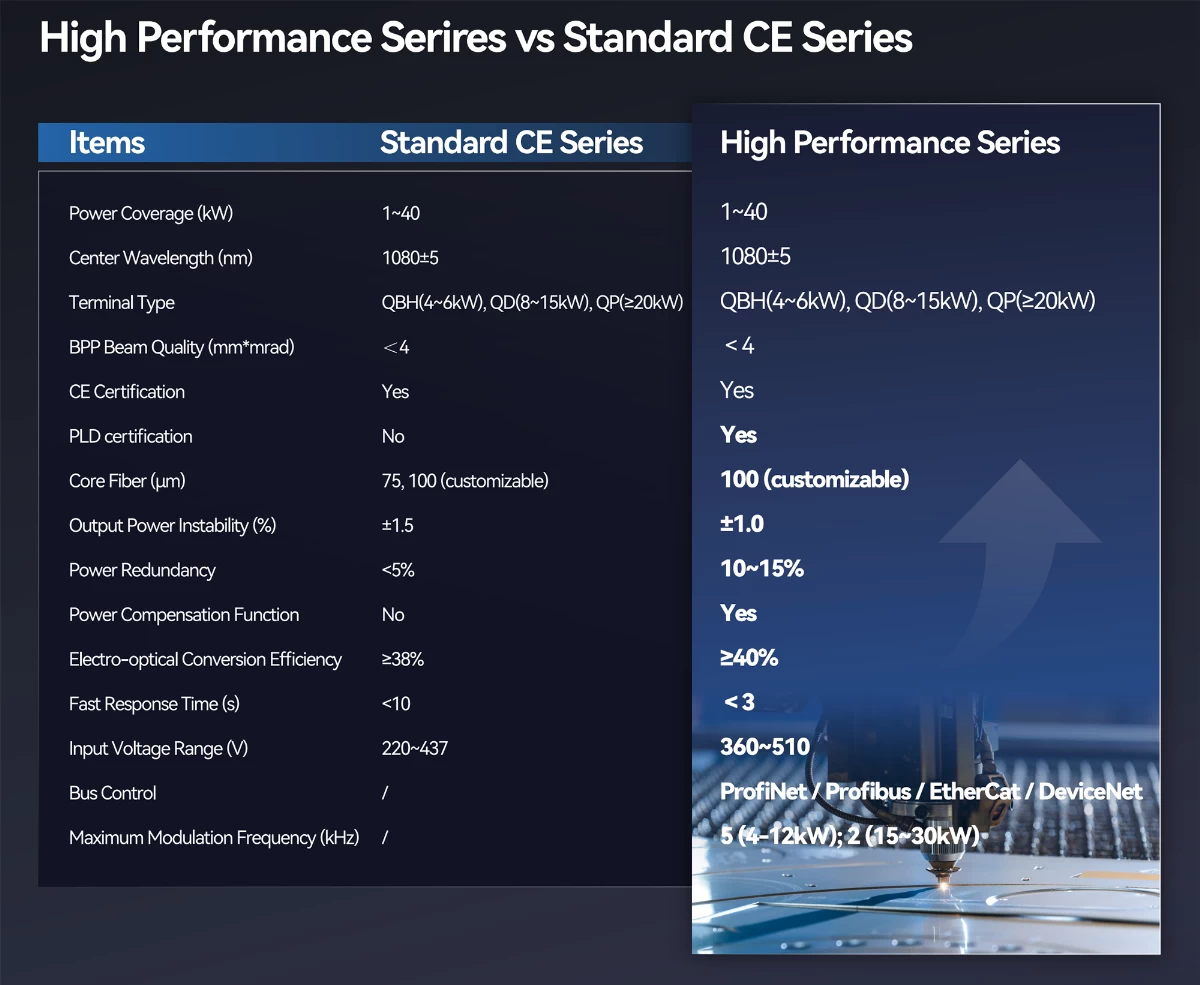

High Performance Series vs Standard Series

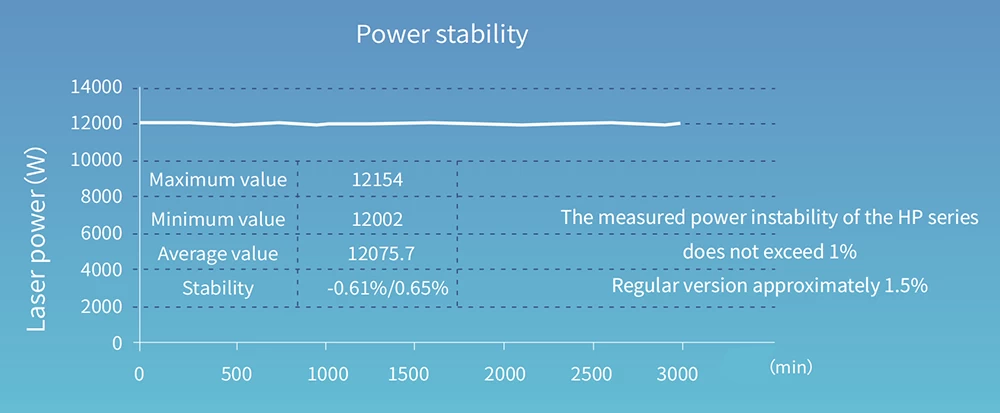

Raycus HP series not only offers significant improvements in efficiency but also achieves world-class power stability. The integration of next-generation intelligent software allows for real-time monitoring of operating parameters, ensuring stable equipment performance and greatly reducing maintenance costs.

Power stability test: Raycus’ anti-interference capability ensures minimal power ripple, achieving international first-class performance.

With the configuration of the upper-level software, visible light, feedback light, and leakage light signals are monitored, allowing real-time control of the system status.

Bluetooth connection via the mobile app enables real-time dynamic smart monitoring of operating parameters.

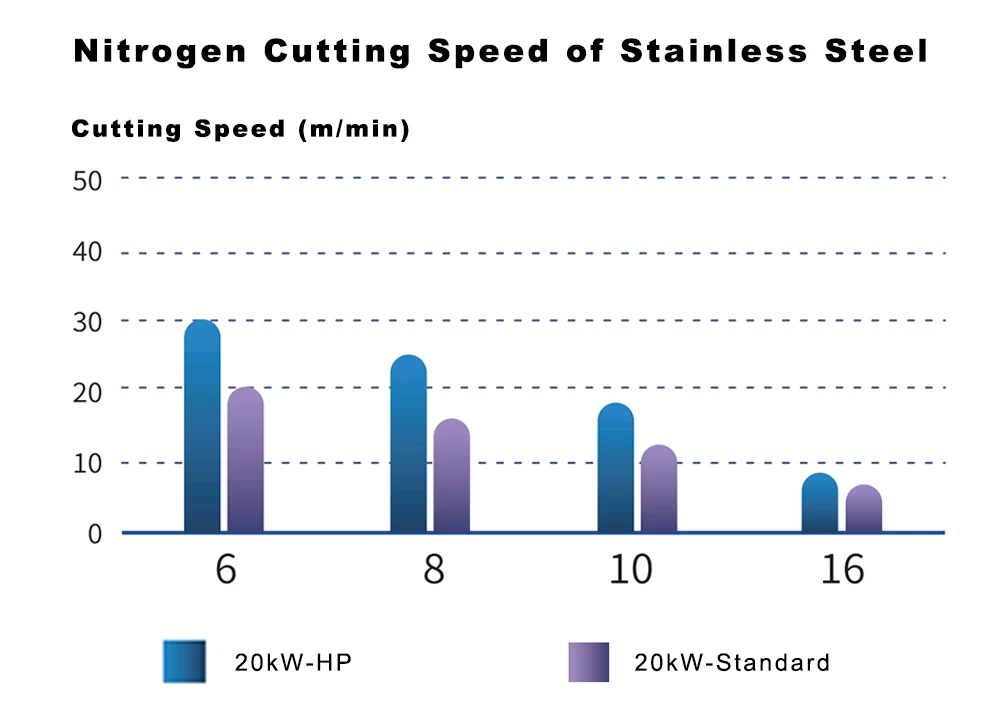

Significant Improvement in Processing Efficiency

Measured data shows that the Raycus HP high-performance series lasers offer significant improvements in processing efficiency compared to standard lasers of the same power.

When compared to the standard 20,000W version, the Raycus RFL-C20000M-HP 20000W laser shows a 33%-60% improvement in cutting efficiency for thin sheets in the 6-16mm range. For instance, cutting 6mm thin sheets with the RFL-C20000M-HP is up to 60% faster than with the standard 20,000W laser. Based on 16 hours of processing per day and 30 working days per month, the monthly revenue using the HP series 20,000W can increase by 56.25%.

RFL-C20000M-HP – Nitrogen Cutting Speed of Stainless Steel

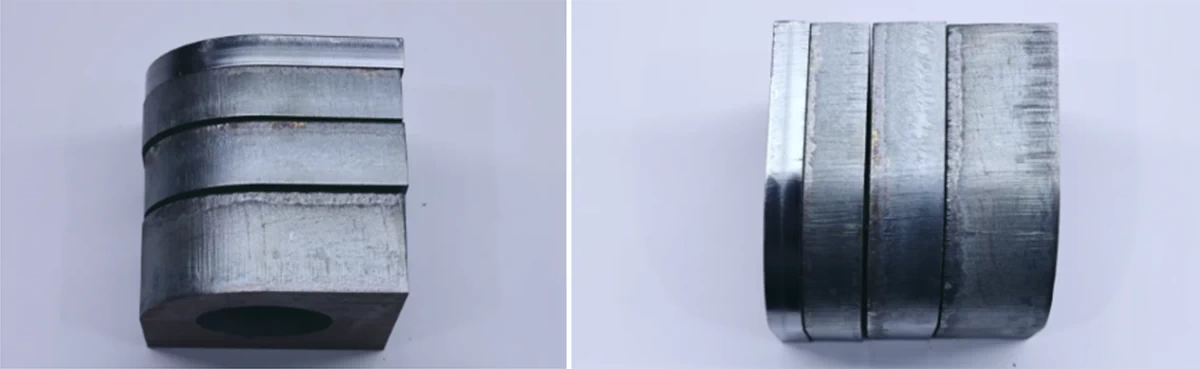

Better Processing Quality

In practical laser cutting applications, Raycus HP high-performance lasers offer faster speeds, better cut quality, and lower production costs, significantly improving both efficiency and quality.

Taking 20mm thick plates as an example, the Raycus RFL-C6000S-HP outperforms the standard 6000W laser significantly, not only in terms of efficiency but also in the quality of the cut. The cut surfaces processed with the HP series are cleaner and of higher quality.

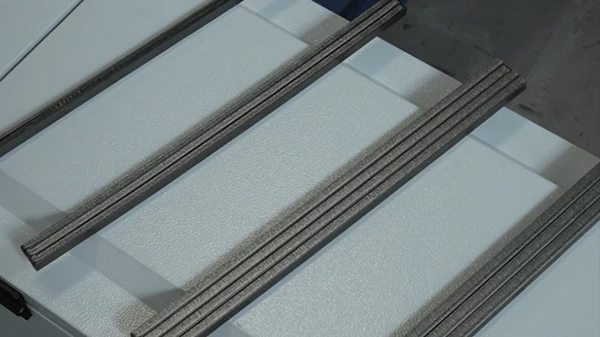

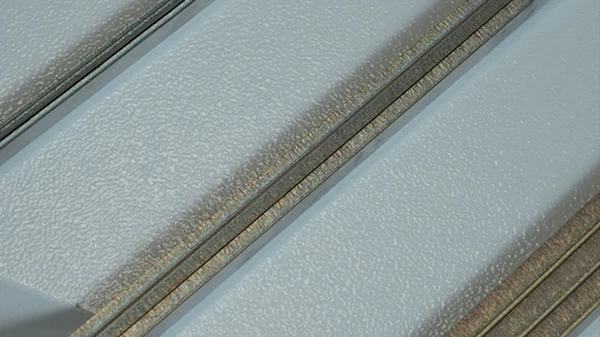

Oxygen cutting surface quality for 20mm and 30mm carbon steel

Below are the cutting surface examples of Raycus high-performance CW fiber lasers on stainless steel, carbon steel, and brass at different thicknesses:

Carbon Steel – 3mm, 6mm, 10mm

Stainless Steel – 3mm, 6mm, 10mm

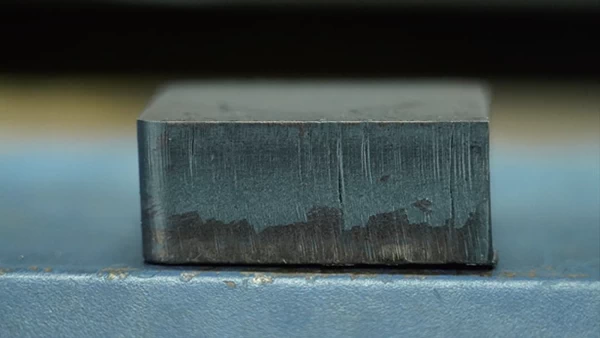

Carbon Steel – 14mm

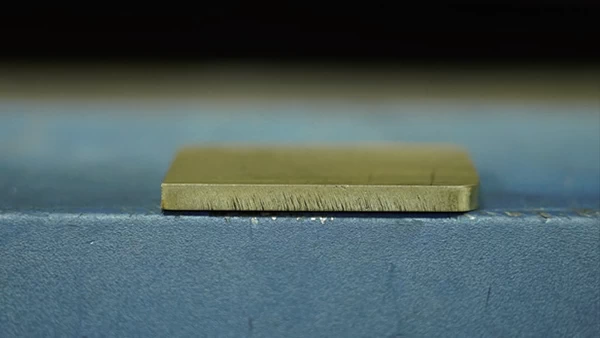

Brass – 4mm

Related Products

Share The Post Now:

You Might Also Like

Yupec Laser is a leading provider of advanced fiber laser solutions in Europe, specializing in the sales, technical support, and service of Raycus fiber lasers.

With years of experience and a team of industry experts, we will be happy to help you with all your laser and laser application needs.

For more information about our products and services, please feel free to get in touch with us. We look forward to collaborating with you and driving innovation together.